IPC Soldering Courses

IPC Soldering Courses

Basic solder skills can be learned easily

Many YouTube videos could teach you the basics, some are good, most less so, but you can be taught how to solder relatively quickly.

Why is it then that many electronics manufacturing companies in the aerospace, motorsport and defence sectors have problems with solder skills?

It is because, as with everything, there is more to it than meets the eye. Even though a team may have learned to solder, there are often discrepancies in levels of knowledge and application which can cause operations to fall over. Here we teach people how to solder from 1st principles. Health and safety, control of ESD, control of FOD, equipment selection, solder selection, tip selection and basic soldering techniques.

If the person who has taught your team worked in a different industry, was taught another way, or did not have the level of understanding required, you’re going to run into problems.

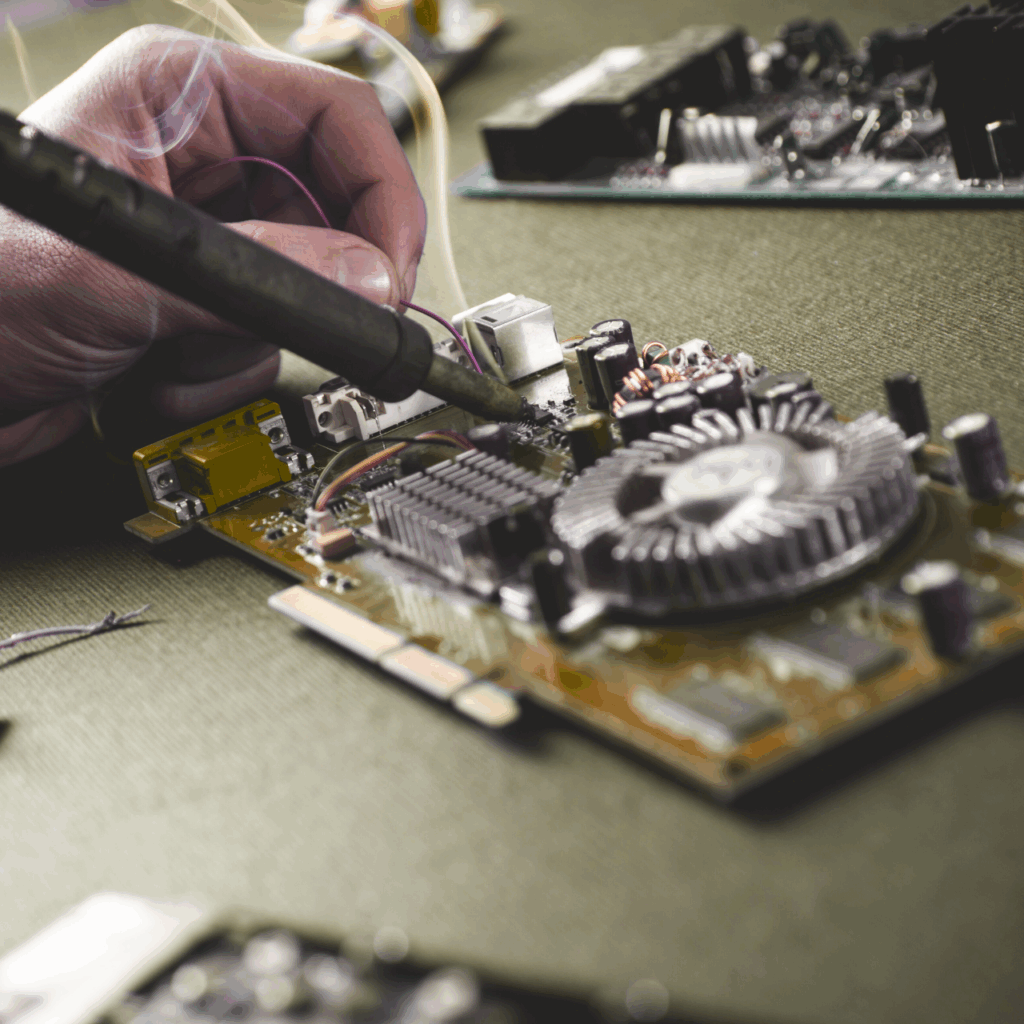

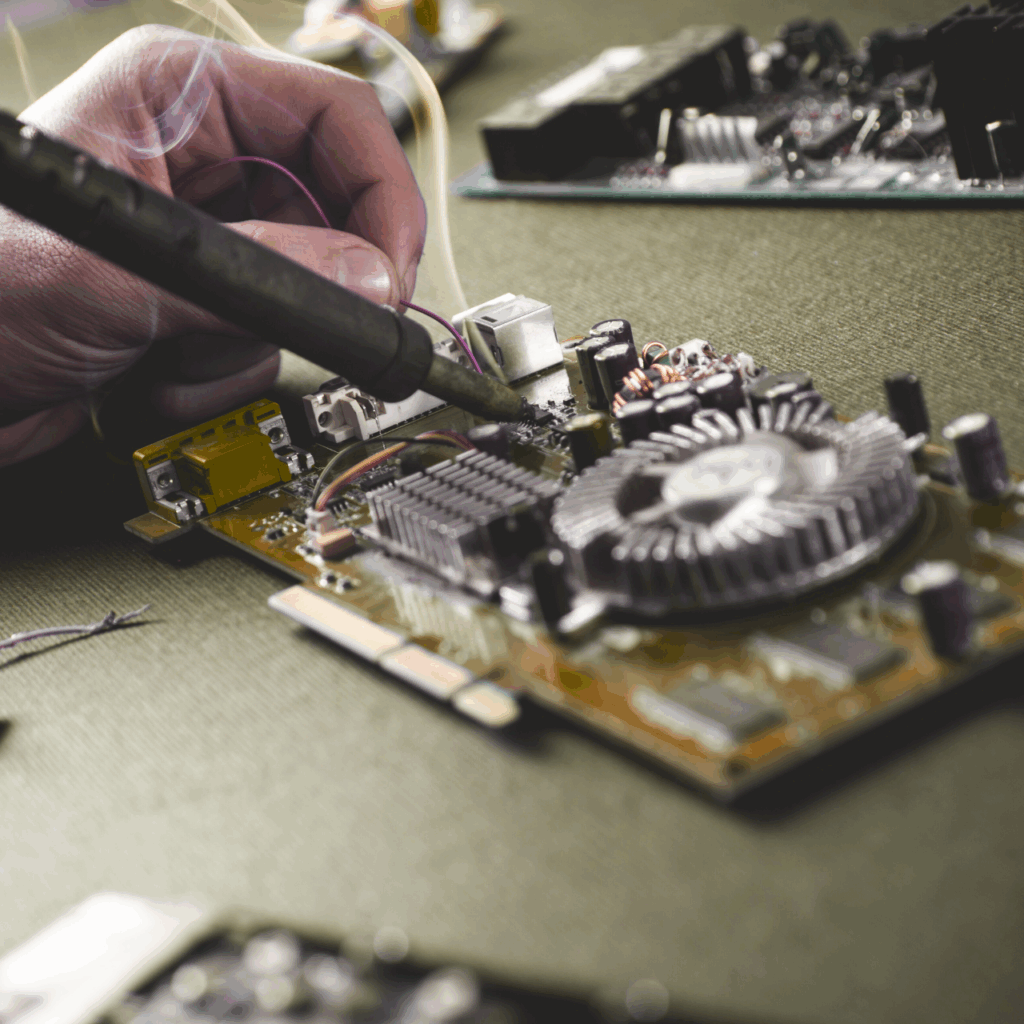

1. The basics

At the very least you should have preoperational and operational safety guidance. Ensuring everything is set up before you begin in the way that it should be, and being aware of how you operate during the soldering process is soldering 101. Things such as a clear and well-ventilated workspace, ensuring solder irons are stored correctly during and after use, and the condition of the soldering tip are all elements your team should be aware of.

Your process after you have completed the operation, and maintenance of your soldering iron is important too – for example, dirty sponges or hard water can negatively affect tip condition.

2. Technique

A whole host of things can affect the tip and its lifespan, so getting your technique right from the start can make a huge difference. High temperatures, surface contamination, excess pressure, and solder feeding, can all negatively affect the quality of your work. There are way too many to list here but safe to say care and control are critical. You also want to avoid revisiting a joint, as this can weaken it.

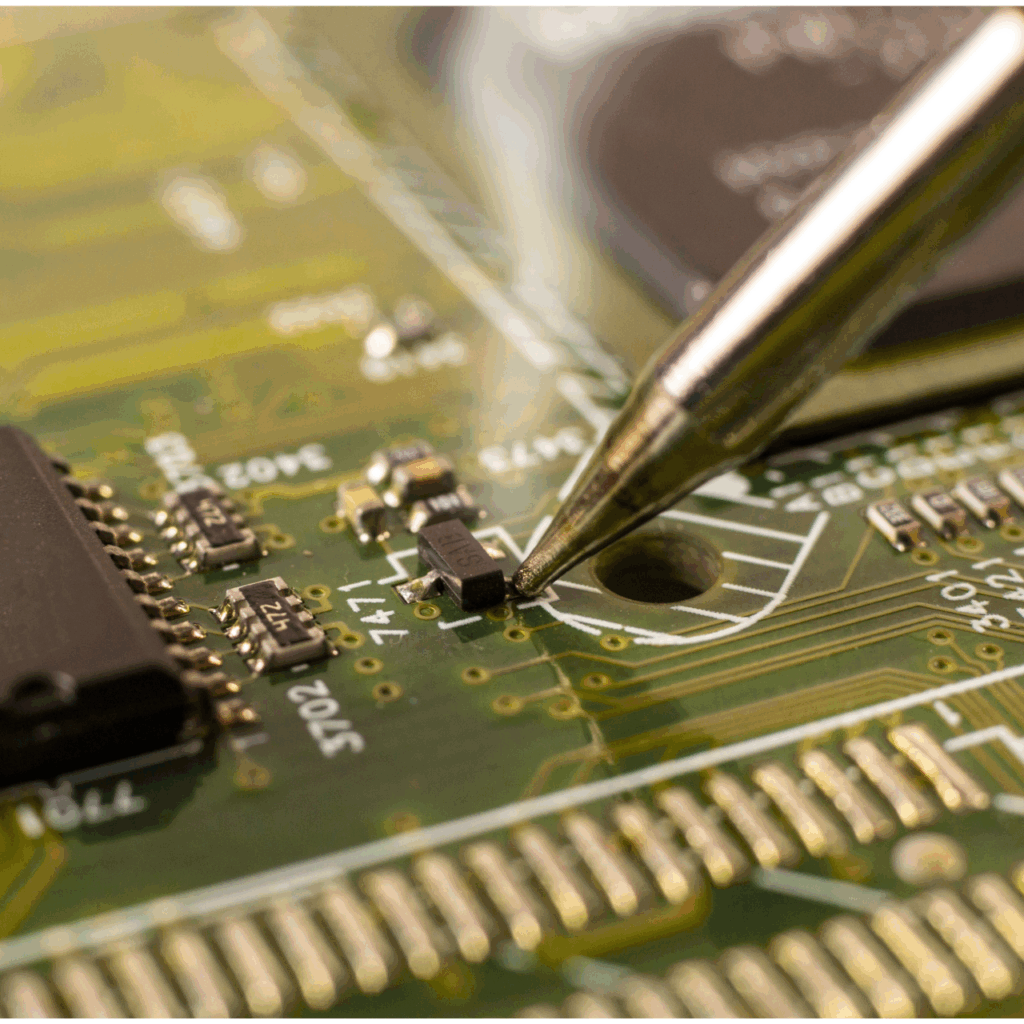

3. Tip Care & Selection

Lastly, the tip you select and how you look after it is important – you’re looking to choose the lowest temperature possible with a geometry that provides the greatest transfer of power. If you choose the wrong tip your operators could end up applying too much pressure, which is not what you want. Equally, too hot and you can damage components, too cool and you won’t activate flux and cause wetting so you can’t solder effectively.

Ultimately it is not purely about adding heat, it’s about how the heat is applied and to where, slowing the process down, knowing what to look for, and protecting your team too.

Basic solder skills can be learned easily

Many YouTube videos could teach you the basics, some are good, most less so, but you can be taught how to solder relatively quickly.

Why is it then that many electronics manufacturing companies in the aerospace, motorsport and defence sectors have problems with solder skills?

It is because, as with everything, there is more to it than meets the eye. Even though a team may have learned to solder, there are often discrepancies in levels of knowledge and application which can cause operations to fall over. Here we teach people how to solder from 1st principles. Health and safety, control of ESD, control of FOD, equipment selection, solder selection, tip selection and basic soldering techniques.

If the person who has taught your team worked in a different industry, was taught another way, or did not have the level of understanding required, you’re going to run into problems.

1. The basics

At the very least you should have preoperational and operational safety guidance. Ensuring everything is set up before you begin in the way that it should be, and being aware of how you operate during the soldering process is soldering 101. Things such as a clear and well-ventilated workspace, ensuring solder irons are stored correctly during and after use, and the condition of the soldering tip are all elements your team should be aware of.

Your process after you have completed the operation, and maintenance of your soldering iron is important too – for example, dirty sponges or hard water can negatively affect tip condition.

2. Technique

A whole host of things can affect the tip and its lifespan, so getting your technique right from the start can make a huge difference. High temperatures, surface contamination, excess pressure, and solder feeding, can all negatively affect the quality of your work. There are way too many to list here but safe to say care and control are critical. You also want to avoid revisiting a joint, as this can weaken it.

3. Tip Care & Selection

Lastly, the tip you select and how you look after it is important – you’re looking to choose the lowest temperature possible with a geometry that provides the greatest transfer of power. If you choose the wrong tip your operators could end up applying too much pressure, which is not what you want. Equally, too hot and you can damage components, too cool and you won’t activate flux and cause wetting so you can’t solder effectively.

Ultimately it is not purely about adding heat, it’s about how the heat is applied and to where, slowing the process down, knowing what to look for, and protecting your team too.