IPC -7711/7721 Training Course and Certification

IPC -7711/7721 Training Course and Certification

IPC – 7711/7721: Rework, Modification, and Repair of Electronic Assemblies

The IPC – 7711/7721 is an internationally recognised qualification for reworking, modification and repair of electronic assemblies. It is crucial for your business if you are looking to reduce the amount of scrap and rework costs and reduce waste.

The IPC-7711/7721 is an internationally recognised qualification that serves as the gold standard for professionals involved in reworking, modifying, and repairing electronic assemblies. This certification is crucial for organisations seeking to significantly reduce scrap and rework costs, minimise waste, and improve operational efficiency in electronics manufacturing.

When you want to reduce costs and increase profit margins in your electronics manufacturing, the first thing you tend to do is look at your processes and bottom line. There are many ways in which you can tighten up your processes (see our blog here – focusing on your people to reduce scrap and rework costs), but this course focuses on the specific knowledge and skills needed to rework, repair or modify boards and electronic assemblies.

The course will cover procedure guidelines, required tools and materials, and techniques for removing and replacing components and conformal coatings.

While aerospace, defence and motorsport electronics manufacturers usually work to Class 3, the training and its standard covers all three classes – Class 1, Class 2 and Class 3.

(We discuss the different class levels in our blog – Electronics Manufacturing – mastering soldering basics)

This course is aimed at operators involved in PCB assembly repairs and rework. A combination of theory and practical work that will test the ability to remedy problems to any product classification, this course ensures the long-life operation of the assembly. Ensuring proficiency in these skills can lead to significant cost efficiencies for your organisation.

What does the IPC 7711/7721 Certification cover?

The IPC–7711/7721 course explores the various industry-approved techniques for reworking or repairing electrical or electronic assemblies and covers the following:

- Wire Splicing

- Conformal coat identification and removal

- Through-hole components

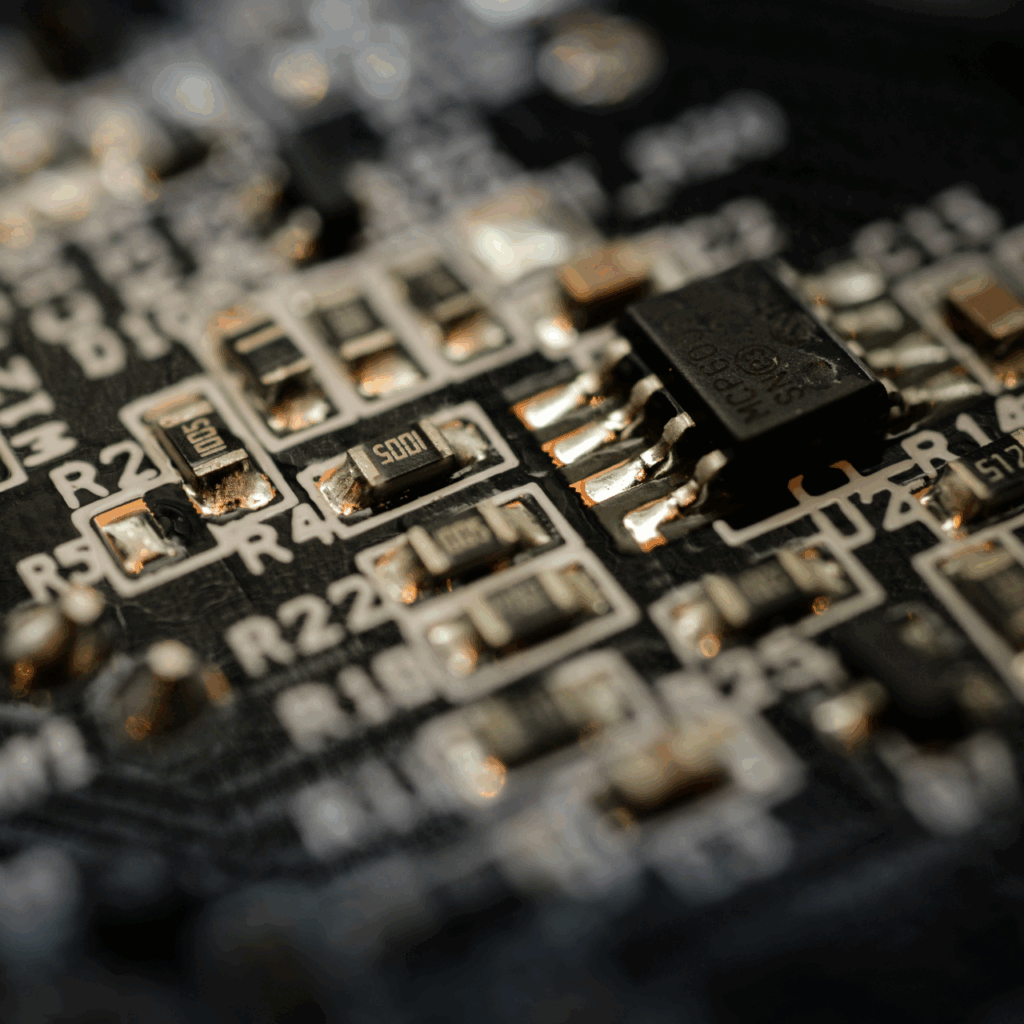

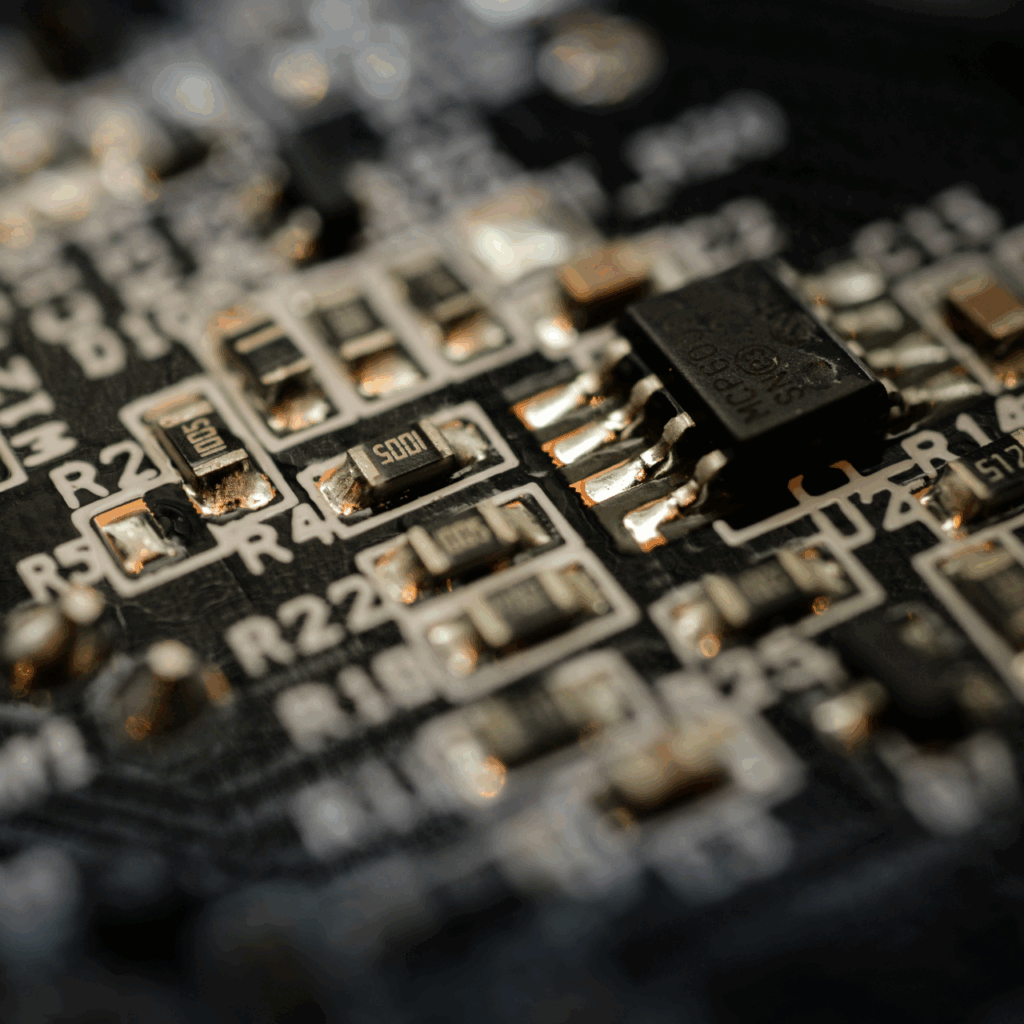

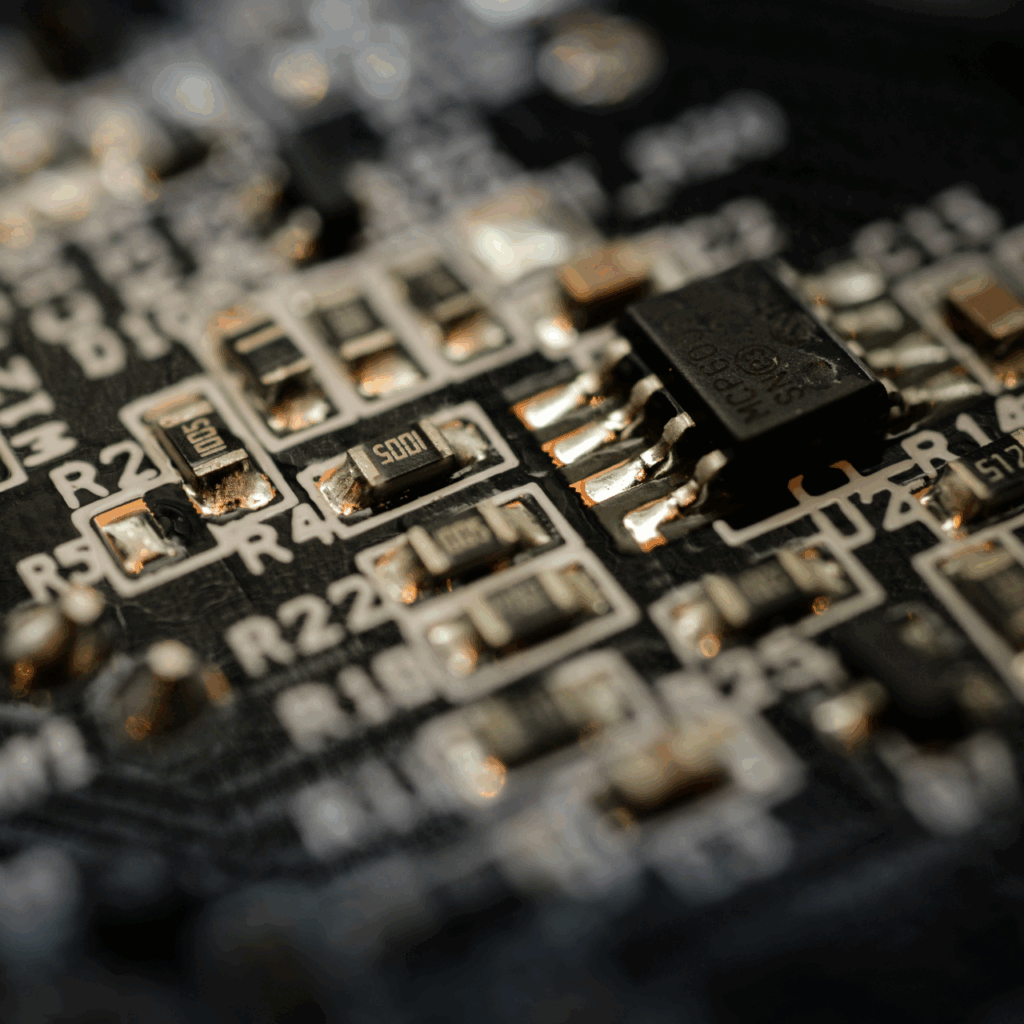

- Chip Components (Surface Mount)

- Gull Wing Components (Surface Mount)

- J Lead Components (Surface Mount)

- Laminate Repair

- Conductor Repair

The certification usually takes four days and is valid for two years. You can recertify within three months before expiry, but if your certificate expires, you’ll need to take the full course again.

Soldering and High Voltage

Through Hole Components

Terminal Connections

Surface Mounted Components

Surface Mount (SMT)

Conformal Coat Identification and Removal

IPC 7711/7721 Training: Who is it for?

This specialised course is designed for operators and technicians directly involved in PCB assembly repairs and rework processes. Through a carefully balanced combination of theoretical knowledge and practical hands-on work, attendees will develop and demonstrate the ability to remedy problems across any product classification, ensuring the long-term operational reliability of electronic assemblies.

Aimed at those who are responsible for reworking or repairing electrical or electronic assemblies, this is not a course for beginners. We recommend attendees have a strong understanding of components, soldering processes, and electronics assemblies. If you need some basic solder training, we do provide this—please check out our solder and handling training.

Investing in these specialised skills can lead to significant cost efficiencies and competitive advantages for your organisation in today’s challenging electronics manufacturing environment.

Why IPC-7711/7721 Matters to Your Business

Examining your processes and the bottom line is critical when striving to reduce costs and increase profit margins in electronics manufacturing, particularly those in high-performance environments in the motorsport, aerospace, and defence industries.

While there are numerous approaches to streamlining operations (as detailed in our blog on focusing on your people to reduce scrap and rework costs), the IPC-7711/7721 certification specifically addresses the specialised knowledge and technical skills required to modify, rework, and repair electronic assemblies to industry standards effectively.

This globally recognised standard provides reliable, repeatable, and safe methods for working with both surface mount and through-hole components.

By implementing these industry-approved techniques, your business will:

- Achieve substantial cost savings: Eliminate the need to scrap defective assemblies by implementing proper repair procedures

- Extend product lifecycles: Prolong the operational life of electronic products through efficient repair and modification techniques

- Restore quality assurance: Ensure that repaired and reworked assemblies meet or exceed quality standards across all classification levels

- Develop Technical Expertise: Build internal capabilities that reduce dependency on external repair services

- Enhance manufacturing resilience: Create more robust production processes by having certified repair specialists on your team

Job roles suitable for this training are Rework Operators, Manufacturing Engineers, Repair Engineers and Quality Inspectors

What is included?

IPC–7711/7721 training can be delivered on-site at your business or at our dedicated training centre so you can upskill your team in the most cost-effective way for your business.

If you choose to have group training delivered on-site at your business you will need to provide a suitable dedicated learning environment, relevant equipment and presentation tech.

If you choose to book a course at our official IPC Certification centre in the Midlands, all the highest quality equipment is provided.

For either option Practical Assessment kits and Certificates will be provided.

Download Course Overview

IPC – 7711/7721: Rework, Modification, and Repair of Electronic Assemblies

The IPC – 7711/7721 is an internationally recognised qualification for reworking, modification and repair of electronic assemblies. It is crucial for your business if you are looking to reduce the amount of scrap and rework costs and reduce waste.

The IPC-7711/7721 is an internationally recognised qualification that serves as the gold standard for professionals involved in reworking, modifying, and repairing electronic assemblies. This certification is crucial for organisations seeking to significantly reduce scrap and rework costs, minimise waste, and improve operational efficiency in electronics manufacturing.

When you want to reduce costs and increase profit margins in your electronics manufacturing, the first thing you tend to do is look at your processes and bottom line. There are many ways in which you can tighten up your processes (see our blog here – focusing on your people to reduce scrap and rework costs), but this course focuses on the specific knowledge and skills needed to rework, repair or modify boards and electronic assemblies.

The course will cover procedure guidelines, required tools and materials, and techniques for removing and replacing components and conformal coatings.

While aerospace, defence and motorsport electronics manufacturers usually work to Class 3, the training and its standard covers all three classes – Class 1, Class 2 and Class 3.

(We discuss the different class levels in our blog – Electronics Manufacturing – mastering soldering basics)

This course is aimed at operators involved in PCB assembly repairs and rework. A combination of theory and practical work that will test the ability to remedy problems to any product classification, this course ensures the long-life operation of the assembly. Ensuring proficiency in these skills can lead to significant cost efficiencies for your organisation.

What does the IPC 7711/7721 Certification cover?

The IPC–7711/7721 course explores the various industry-approved techniques for reworking or repairing electrical or electronic assemblies and covers the following:

- Wire Splicing

- Conformal coat identification and removal

- Through-hole components

- Chip Components (Surface Mount)

- Gull Wing Components (Surface Mount)

- J Lead Components (Surface Mount)

- Laminate Repair

- Conductor Repair

The certification usually takes four days and is valid for two years. You can recertify within three months before expiry, but if your certificate expires, you’ll need to take the full course again.

Soldering and High Voltage

Through Hole Components

Terminal Connections

Surface Mounted Components

Surface Mount (SMT)

Conformal Coat Identification and Removal

Terminal Connections

Surface Mounted Components

Surface Mount (SMT)

IPC 7711/7721 Training: Who is it for?

This specialised course is designed for operators and technicians directly involved in PCB assembly repairs and rework processes. Through a carefully balanced combination of theoretical knowledge and practical hands-on work, attendees will develop and demonstrate the ability to remedy problems across any product classification, ensuring the long-term operational reliability of electronic assemblies.

Aimed at those who are responsible for reworking or repairing electrical or electronic assemblies, this is not a course for beginners. We recommend attendees have a strong understanding of components, soldering processes, and electronics assemblies. If you need some basic solder training, we do provide this—please check out our solder and handling training.

Investing in these specialised skills can lead to significant cost efficiencies and competitive advantages for your organisation in today’s challenging electronics manufacturing environment.

Why IPC-7711/7721 Matters to Your Business

Examining your processes and the bottom line is critical when striving to reduce costs and increase profit margins in electronics manufacturing, particularly those in high-performance environments in the motorsport, aerospace, and defence industries.

While there are numerous approaches to streamlining operations (as detailed in our blog on focusing on your people to reduce scrap and rework costs), the IPC-7711/7721 certification specifically addresses the specialised knowledge and technical skills required to modify, rework, and repair electronic assemblies to industry standards effectively.

This globally recognised standard provides reliable, repeatable, and safe methods for working with both surface mount and through-hole components.

By implementing these industry-approved techniques, your business will:

- Achieve substantial cost savings: Eliminate the need to scrap defective assemblies by implementing proper repair procedures

- Extend product lifecycles: Prolong the operational life of electronic products through efficient repair and modification techniques

- Restore quality assurance: Ensure that repaired and reworked assemblies meet or exceed quality standards across all classification levels

- Develop Technical Expertise: Build internal capabilities that reduce dependency on external repair services

- Enhance manufacturing resilience: Create more robust production processes by having certified repair specialists on your team

Job roles suitable for this training are Rework Operators, Manufacturing Engineers, Repair Engineers and Quality Inspectors

What is included?

IPC–7711/7721 training can be delivered on-site at your business or at our dedicated training centre so you can upskill your team in the most cost-effective way for your business.

If you choose to have group training delivered on-site at your business you will need to provide a suitable dedicated learning environment, relevant equipment and presentation tech.

If you choose to book a course at our official IPC Certification centre in the Midlands, all the highest quality equipment is provided.

For either option Practical Assessment kits and Certificates will be provided.