IPC Standards

Need IPC Standards Training?

Make Sure You Contact Us!

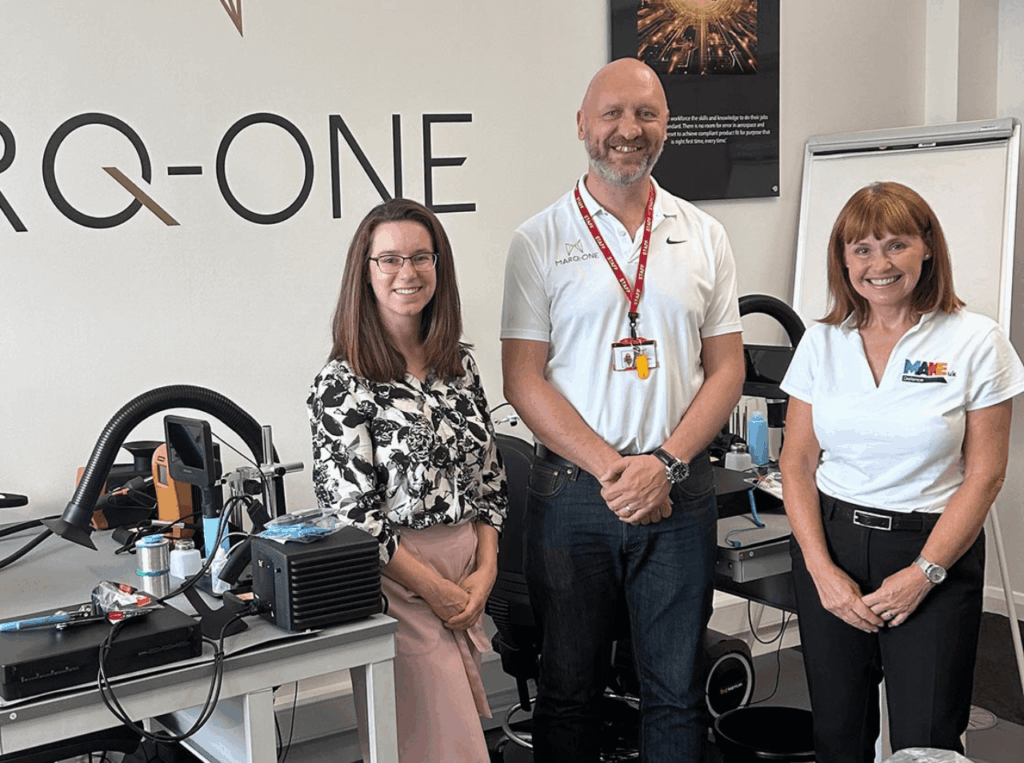

At Marq-One, we know that precision and reliability in electronics manufacturing are essential to achieving high-quality results. That’s why we use our extensive industry expertise to deliver IPC-certified training designed to equip engineers, technicians, and production teams with the skills and credentials to consistently meet the highest standards in the sector.

Whether you operate in aerospace, defence, motorsport, or advanced electronics, our training gives your team the knowledge and confidence to perform with accuracy, reduce errors, and ensure your products meet globally recognised standards.

As an authorised IPC training provider, we offer certification across the full spectrum of IPC standards, including IPC-A-610, IPC/WHMA-A-620, IPC-J-STD-001 with Space Addendum, IPC-7711/7721, IPC-A-600, and IPC-6012.

Each course is delivered by instructors equipped with decades of practical experience, ensuring learning goes beyond theory to real-world application.

Why IPC Training Matters For Your Team

Electronics manufacturing is constantly evolving, with increasing demands for precision, reliability, and compliance. But IPC certification isn’t just about meeting a requirement — it’s about giving your team the tools to produce high-quality work every time.

With Marq-One, training is practical, hands-on, and tailored to the needs of your organisation. Our instructors draw on years of industry experience to provide insights that go beyond textbooks, helping your team apply IPC standards effectively from day one.

Whether training a small group or certifying an entire production team, we provide all the flexibility you need: courses are available at our Nuneaton training centre or on-site at your facility, minimising disruption while maximising impact.

IPC-A-610: Setting The Standard For Assembly Acceptability

IPC-A-610 is recognised worldwide as the definitive standard for electronic assembly acceptability. Our IPC-A-610 course will ensure your team understands how to identify acceptable, defective, and nonconforming assemblies across all product classes — Class 1, 2, and 3.

Participants gain practical skills in inspecting solder joints, component placement, lead dressing, and mechanical assembly features. The result is a workforce capable of reducing defects, improving consistency, and ensuring assemblies meet the expectations of demanding clients.

IPC/WHMA-A-620: Mastering Cable And Wire Harness Assembly

The IPC/WHMA-A-620 standard defines the criteria for cable and wire harness assemblies, a crucial area for high-reliability applications. Our course teaches participants to assemble, inspect, and verify harnesses to meet these exacting standards.

From crimping and soldering to shielding and connectorisation, delegates learn to produce reliable, consistent assemblies. This training is invaluable for teams supplying aerospace, automotive, or industrial systems, where the quality of wiring directly impacts performance and safety.

IPC-7711/7721: Rework, Repair, And Modification

Sometimes, assemblies require repair, modification, or component replacement. The IPC-7711/7721 standard defines how to perform these tasks without compromising reliability.

Our course covers rework techniques for surface-mount and through-hole components, pad and conductor repair, and assembly modification.

Delegates learn to restore boards to meet Class 3 requirements, reducing scrap and maintaining performance. This training ensures your team can handle high-value electronics safely and effectively.

IPC-J-STD-001 And Space Addendum: Soldering Excellence

For teams working with critical electronics, IPC-J-STD-001 provides the framework for soldered electrical and electronic assemblies, while the Space Addendum addresses the additional demands of mission-critical applications in industries such as aerospace and defence.

Our course teaches the soldering techniques, materials, and verification processes required for Class 3 and space-qualified assemblies. Delegates will also gain the practical experience needed to ensure assemblies perform reliably under extreme conditions.

IPC-6012: Rigid PCB Qualification And Performance

The IPC-6012 standard sets the requirements for rigid printed boards in high-reliability applications. Our course guides participants through material selection, plating, conductor characteristics, solder mask evaluation, and dimensional tolerances.

Delegates gain the skills to assess boards according to Class 3 standards, ensuring every PCB entering production is suitable for mission-critical assemblies. This training supports compliance, reliability, and traceability across all stages of production.

IPC-A-600: Ensuring Printed Board Quality

Quality control starts with the bare PCB. IPC-A-600 provides clear guidance on what constitutes an acceptable board. Marq-One’s training teaches participants to inspect for defects such as plating voids, delamination, conductor irregularities, and solder mask issues.

Inspectors, quality engineers, and fabricators leave the course equipped to identify potential problems early, preventing defects from reaching assembly lines and improving overall manufacturing outcomes.

The Real-World Benefits For Your Organisation

Achieving IPC certification with Marq-One provides measurable advantages. Teams develop competence in assembly, inspection, and repair, resulting in improved production quality, reduced defects, and greater operational efficiency.

For companies in sectors such as aerospace, defence, automotive, and motorsport, IPC certification is often a contractual requirement. Having certified staff demonstrates capability to clients and auditors, strengthens supply chain credibility, and ensures your organisation remains competitive.

Flexible And Accessible Training Delivery

We offer training at our Nuneaton centre or on-site at your facility. On-site training is ideal for organisations looking to train large teams in their own environment, while our centre provides a controlled, focused learning experience for smaller groups.

All courses include hands-on practical assessments and industry-recognised certification valid for two years, with clear options for recertification to maintain compliance.

Expert Training Backed By Industry Experience

What sets Marq-One apart is our practical approach.

Our instructors are experienced professionals who have worked directly with high-reliability electronics in demanding industries. This allows us to deliver training that’s immediately relevant, practical, and tailored to your operation. Delegates will leave with not only the knowledge of IPC standards but also the confidence to apply them effectively in production, inspection, and repair processes.

We’ll work with your organisation to identify the right courses for your requirements, create a tailored training programme, and deliver certification efficiently and professionally. To learn more about our full range of courses, contact our friendly team!