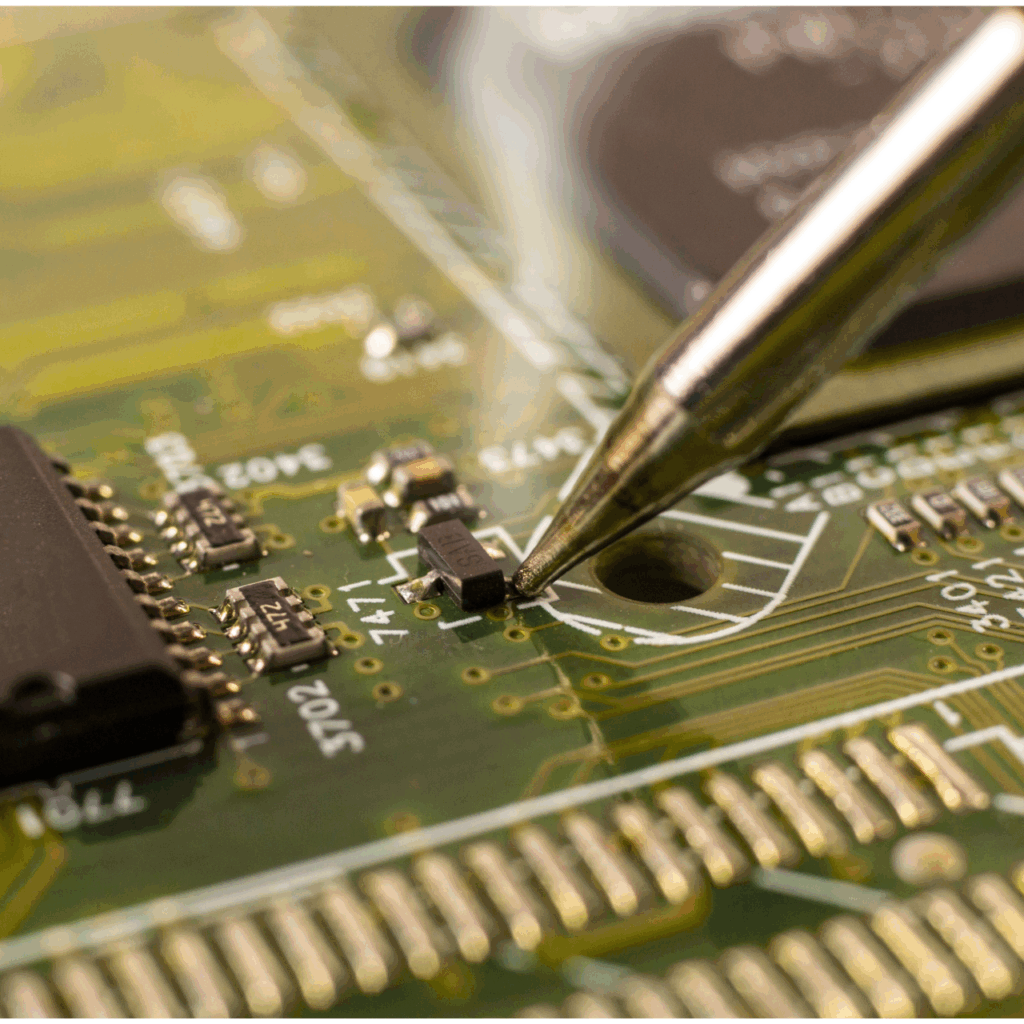

Soldering is a joining process that joins different types of metals together by melting solder. A metal alloy, usually made of tin/lead or a combination of tin/silver/copper, is melted with a hot iron which is heated to temperatures above 185 degrees Celsius, and then cooled to create a strong electrical and mechanical bond.

Basic solder skills can be learned easily – many YouTube videos could teach you the basics, some are really good, some less so, but you can be taught how to solder relatively quickly.

Why is it then that something I bump into a lot in electronics manufacturing is problems with solder skills?

It is because, as with everything, there is more to it than meets the eye. Even though a team may have learned to solder, there are often discrepancies in levels of knowledge and application which can cause operations to fall over.

If the person who has taught your team worked in a different industry, were themselves taught another way, or did not have the level of understanding required, you’re going to run into problems.

Depending on what you are soldering, the function it will have and ultimately where it will end up will require different skills and knowledge levels. You may think your job is to assemble circuit boards, but if you work in aviation, actually your job is to make sure you keep people alive! The result of a faulty circuit board differs massively between a toaster not toasting and an aircraft falling from the sky.

That is why there are different classes of electronic equipment, and why, depending on the application, you may need new or updated skills to ensure you are getting the results from your team that you need.

CLASS 1 General Electronic Products

This includes products suitable for applications where the major requirement is the function of the completed assembly and nothing more

CLASS 2 Dedicated Service Electronic Products

This class includes products where continued performance and extended life is required, and for which uninterrupted service is desired but not critical. Typically the end-use environment would not cause failures.

CLASS 3 High Performance/Harsh Environment Electronic Products

The highest class includes products where continued high performance or performance-on-demand is critical, equipment downtime cannot be tolerated, the end-use environment may be uncommonly harsh, and the equipment must function when required, such as life support or other critical systems.

So – what are soldering basics and are you covering them?

1. Metal Tip Care

At the very least you should have preoperational and operational safety guidance. Ensuring everything is set up before you begin in the way that it should be, and being aware of how you operate during the soldering process is soldering 101. Things such as a clear and well-ventilated workspace, ensuring solder irons are stored correctly during and after use, and the condition of the soldering tip are all elements your team should be aware of.

Your process for after you have completed the operation, and maintenance of your soldering iron is important too – for example, dirty sponges or hard water can negatively affect tip condition.

2. Technique

A whole host of things can affect the tip and its life span, so getting your technique right from the start can make a huge difference. High temperatures, surface contamination, excess pressure, and solder feeding, can all negatively affect the quality of your work. There are way too many to list here but safe to say care and control are critical. You also want to avoid revisiting a joint, as this can weaken it.

3. Tip Selection

Lastly, the tip you select is important – you’re looking to choose the lowest temperature possible with a geometry that provides the greatest transfer of power. If you choose the wrong tip your operators could end up applying too much pressure, which is not what you want. Equally, too hot and you can damage components, too cool and you won’t activate flux and cause wetting so you can’t solder effectively.

It is surprising when you begin to look in more detail quite how many variables there are in a supposedly simple process. Ultimately it is not purely about adding heat, it’s about how the heat is applied and to where, slowing the process down, knowing what to look for, and protecting your team too.

To help address some of the basic gaps in knowledge, I’m currently creating a course to do just that.

I’m going to take a practical and pragmatic approach to improve people’s solder skills in a way that gives your team what they need, but in a cost-effective and minimally disruptive way so it is practical for the business.

I’ll share more as it evolves – drop me a line if you’d be interested!

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]