Printed Circuit Board Failure Analysis

Printed Circuit Board Failure Analysis

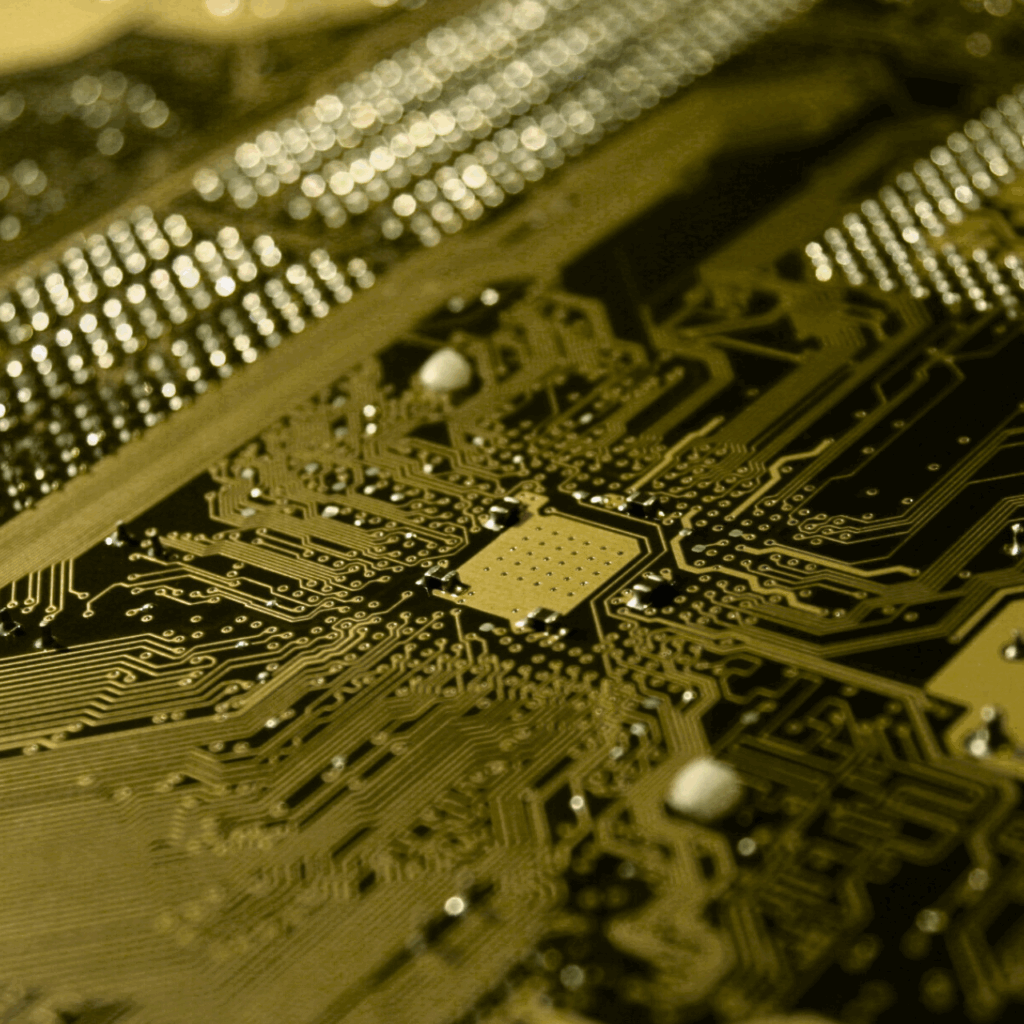

With over two decades in the electronics industry, we’ve seen damage caused to circuit boards that could have easily been avoided with some general electronic cleanliness and handling steps.

Our commitment to excellence meets the unique demands of the motorsport, aerospace, and defence industries. As your dedicated electronics consultancy partner, we bring decades of experience and expertise to enhance and elevate your operations.

You may have found your initial intention of sourcing some IPC training has resulted in opening a proverbial can of worms! Or maybe, you’ve previously invested in training but it doesn’t seem to be having the results you expected. This is where you might need to go deeper into the root issues.

Examples of things that can cause damage are:

- Inconsistent handling practices

- Inadequate handling practices

- Excessive handling of products

- Poorly executed electrical tests eg incorrect/worn-out probes, incorrect pressure settings

- The product incorrectly sent to rework

- Inconsistent application of Electrostatic Discharge (ESD) protocols

- Human factors e.g distraction, not following process, not taking due care

The pattern here is the poor handling of the products. Get the handling right and the incidence of damage will decrease.

Our handling training covers correct handling practices in line with IPC requirements including how to handle PCB assemblies, moisture sensitivity, ESD, FOD, contamination etc.

Why you need this training

By helping your team understand the impact of what they do and equipping them with the skills and abilities to be able to create product right the first time, you can recoup huge savings.

With over two decades in the electronics industry, we’ve seen damage caused to circuit boards that could have easily been avoided with some general electronic cleanliness and handling steps.

Our commitment to excellence meets the unique demands of the motorsport, aerospace, and defence industries. As your dedicated electronics consultancy partner, we bring decades of experience and expertise to enhance and elevate your operations.

You may have found your initial intention of sourcing some IPC training has resulted in opening a proverbial can of worms! Or maybe, you’ve previously invested in training but it doesn’t seem to be having the results you expected. This is where you might need to go deeper into the root issues.

Examples of things that can cause damage are:

- Inconsistent handling practices

- Inadequate handling practices

- Excessive handling of products

- Poorly executed electrical tests eg incorrect/worn-out probes, incorrect pressure settings

- The product incorrectly sent to rework

- Inconsistent application of Electrostatic Discharge (ESD) protocols

- Human factors e.g distraction, not following process, not taking due care

The pattern here is the poor handling of the products. Get the handling right and the incidence of damage will decrease.

Our handling training covers correct handling practices in line with IPC requirements including how to handle PCB assemblies, moisture sensitivity, ESD, FOD, contamination etc.

Why you need this training

By helping your team understand the impact of what they do and equipping them with the skills and abilities to be able to create product right the first time, you can recoup huge savings.