IPC 620

Looking To Achieve The IPC A 620 Standard?

Our Expert-Led Courses Will Get You Certified!

In industries such as electronics, aerospace, automotive, and medical device manufacturing, the precision of cable and wire harness assemblies is critical to product safety, functionality, and performance.

Meeting these requirements often means adhering to strict industry standards, and one of the most crucial of these is IPC-A-620. This standard defines the criteria for the assembly of cable and wire harnesses and is widely recognised across the globe.

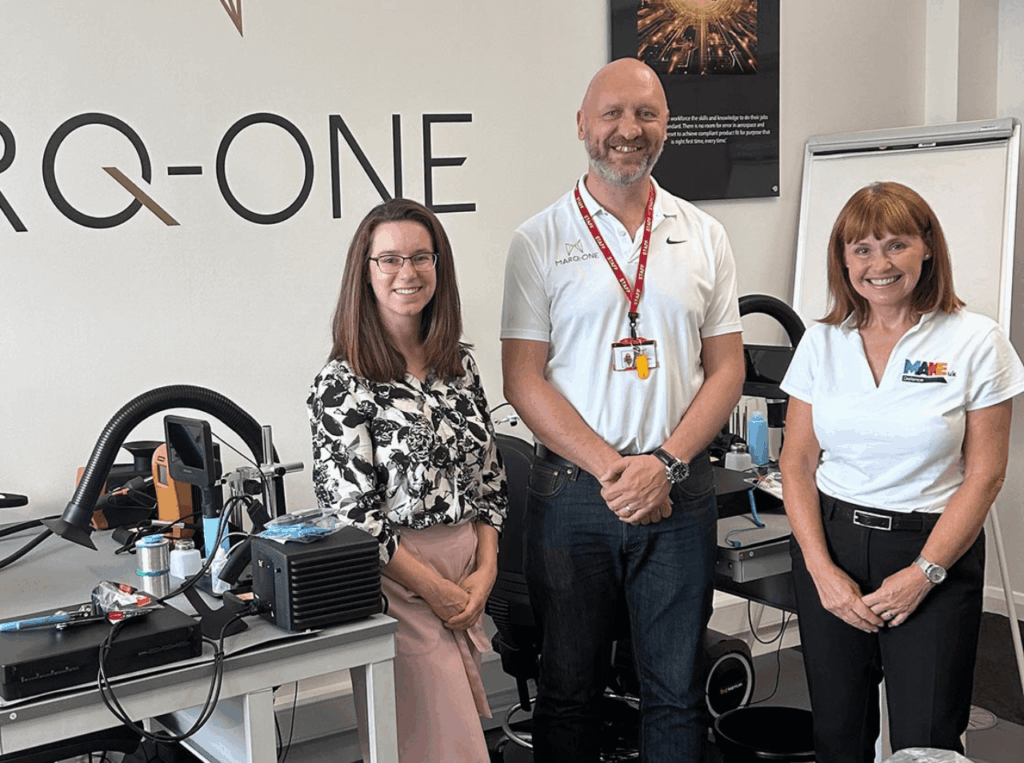

At Marq-One, we offer comprehensive IPC-A-620 training courses and certification programmes that can help your workforce gain the necessary expertise to meet these rigorous standards. Whether you are training new employees or refreshing the skills of your existing team, our training courses ensure they are equipped with the knowledge to produce wire and cable assemblies that meet IPC-A-620’s exacting standards.

Understanding IPC 620: The Global Standard For Cable And Wire Harness Assemblies

Understanding The IPC A 620 Standard: A Global Certification For Cable And Wire Harness Assemblies

The IPC-A-620 standard, developed by the Institute for Printed Circuits (IPC), specifies the requirements for cable and wire harness assemblies used in a wide variety of industries. It outlines the quality standards for materials, processes, and inspection procedures to ensure that these assemblies are reliable and safe for use in high-performance applications. For companies involved in the manufacturing of cables or wire harnesses, understanding and implementing IPC-A-620 is essential to producing products that meet industry expectations and comply with regulatory requirements.

The scope of IPC-A-620 is broad, covering everything from the proper preparation of wires to detailed specifications for assembly techniques like crimping, soldering, and connector installation. It also includes guidelines for the final inspection of cable assemblies, ensuring that they meet strict defect classification criteria.

Whether it’s ensuring the right amount of insulation is stripped from a wire or making sure that a crimped connection meets the required mechanical strength, IPC-A-620 serves as a blueprint for producing high-quality cable and wire harness assemblies. By following these standards, manufacturers can minimise defects, improve reliability, and meet customer expectations more effectively. And for industries such as aerospace or medical devices, where the failure of even a small component can have catastrophic consequences, following IPC-A-620 is non-negotiable.

Why IPC-A-620 Certification Matters

The importance of IPC-A-620 certification goes beyond simply meeting a set of standards—it plays a key role in improving product quality, increasing operational efficiency, and maintaining compliance with industry regulations. By certifying your team members, you ensure that they are well-versed in the methods and processes required to produce top-tier cable and wire harness assemblies.

One of the primary benefits of IPC-A-620 certification is the improvement in product quality. Employees who are trained and certified in IPC-A-620 are equipped with the knowledge and practical skills to produce assemblies that meet the highest standards. This directly impacts the final product’s reliability, reducing the likelihood of defects or issues that could result in costly rework, delays, or customer complaints. Additionally, properly trained staff are more adept at identifying potential issues early, which helps to mitigate problems before they escalate, ultimately reducing operational costs.

Beyond improving quality, IPC-A-620 certification ensures consistency across your production line. With standardised training, every team member works according to the same criteria, applying uniform techniques to produce cable assemblies. This eliminates variation between workers and ensures that your products meet the same high standards every time, regardless of the individual involved.

IPC-A-620 certification can also give your company a competitive edge. Many clients, particularly in regulated sectors like medical devices and aerospace, require their suppliers to adhere to this standard. By demonstrating that your team is IPC certified, you increase your chances of securing contracts with high-value clients who demand exceptional quality and regulatory compliance. This is not just an internal advantage but a powerful marketing tool for expanding your business.

Lastly, IPC-A-620 certification supports regulatory compliance. In industries where safety and reliability are paramount, adhering to recognised standards like IPC-A-620 is often a requirement. Being certified helps ensure that your products meet the necessary regulations, reducing the risk of legal or safety issues arising from non-compliant assemblies.

How Marq-One Helps Your Team With Expert IPC 620 Training

At Marq-One, we believe that effective training is more than just about passing an exam—it’s about equipping your team with the skills and knowledge they need to perform at their best. Our IPC-A-620 training courses are designed to provide both theoretical knowledge and practical, hands-on experience, so your team members can apply what they’ve learned directly to their work.

Our instructors are seasoned professionals with extensive experience in the cable and wire harness industry. They don’t just teach the material—they bring real-world insights and practical advice that make the training experience highly relevant and applicable. By learning from instructors with industry experience, your employees gain a deeper understanding of the challenges and best practices involved in cable assembly.

To meet the diverse needs of businesses, Marq-One offers flexible training options. We can provide on-site training at your facility, which is especially useful for businesses looking to train a large number of employees without disrupting their operations. Alternatively, for teams that are geographically dispersed or prefer a remote learning option, we offer virtual instructor-led training. This approach allows your employees to learn from anywhere, with the added benefit of real-time interaction with instructors.

And for those who prefer a traditional classroom setting, we also offer in-person training at our centrally located facilities. This setting provides a focused environment conducive to learning, where employees can engage directly with the instructor and other trainees.

Each of our courses is designed to be practical and hands-on, with real-world exercises that mimic the conditions your employees will face in their daily work. From crimping wires to performing final inspections, our training includes exercises that give participants the experience they need to perform their jobs with confidence.

Course Content: What Will Your Team Learn?

Marq-One’s IPC-A-620 training covers all aspects of cable and wire harness assembly, ensuring that your team members understand each step of the process in detail.

The course starts with an overview of the IPC-A-620 standard itself, covering its scope, purpose, and importance in various industries. Participants will then learn about wire preparation techniques, including stripping, cutting, and handling wires to ensure they are ready for assembly.

The course also dives into the crucial skills of soldering and crimping, teaching participants how to achieve proper terminations for connectors. This is an essential aspect of cable and wire harness assembly, as improper crimping or soldering can result in poor mechanical strength or electrical failure. The training also includes specific guidelines for the assembly process, teaching participants how to follow best practices for routing, bundling, and insulating wires, as well as ensuring correct connector and component placement.

Another critical area of training focuses on inspection procedures, where employees will learn how to visually inspect cable assemblies for defects and meet the IPC-A-620 defect classification criteria. Participants will be trained on how to identify issues such as improper crimping, damaged insulation, or incorrect wire lengths, and how to address these problems to ensure compliance with the standard.

Finally, safety is a key aspect of our training. The course includes guidance on how to work safely with tools and materials, ensuring that your team members adhere to both industry standards and internal safety protocols.

Why Choose Us For Training On The IPC A 620 Standard?

Marq-One is well-regarded a trusted provider of IPC-A-620 training because of our dedication to delivering high-quality, practical experiences that directly benefit your business. Our instructors bring years of experience in the field, ensuring that the knowledge passed on to your team is both up-to-date and highly relevant to real-world applications.

And as we offer customised training options to suit your specific needs – whether it’s on-site training at your facility, virtual instruction for remote teams, or classroom-based learning – the flexibility we offer ensures that your employees can receive top-tier training without disrupting your operations.

Contact Us If You Want To Achieve IPC-A-620 Certification!